How To Replace a Seal on a Frank Bacon FB- Hydraulic Series Machines

- First remove the screws from the upper screw covers from both upper and middle crossheads.

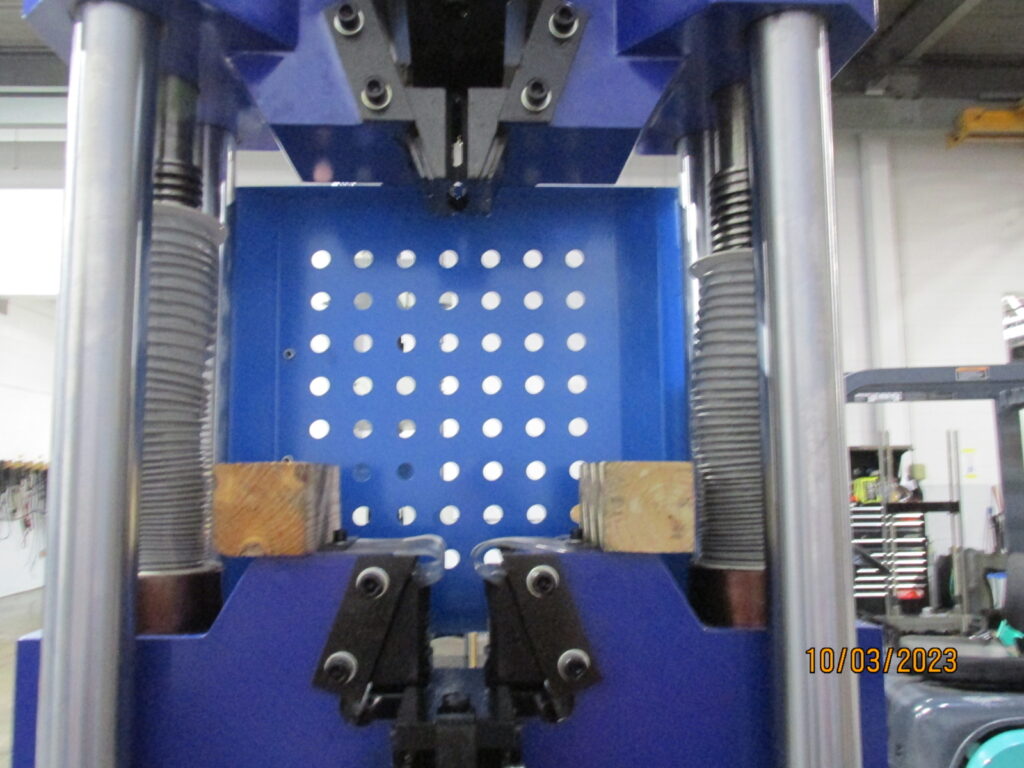

- Then place 2 4×4 blocks on top of the middle crosshead.

- Remove Grip hoses from the crossheads to allow room to move the entire section upwards and not put strain on the hydraulic hoses/fittings.

- Remove the pressure line from the side of the frame. You can cap the console side but leave the frame side open and place a bucket under the fitting to catch the hydraulic oil. When reassembling this will also spray oil out so have buckets and rags available. Remove the main 4 panels from the base of the frame. Remove the string pot encoder line from the hook on the table.

- Remove the black limit switch trip bar from underneath the table.

- Run the crosshead all the way to the top making sure that the nuts do not run off of the screws! The crosshead motor is likely not strong enough to push both crossheads up so when the boards touch the top crosshead that should be good enough.

- Measure the distance between the top of the table and the bottom of the middle crosshead. It needs to be at least 18” a little more makes it easier.

- Now disconnect the power

- You need to remove the limit switch wires and the control box wires from the main gray electrical box mounted on the base of the machine.

- Then you need to cut all of the zip ties connecting the wires as well

- On the back of the frame we need to free up the load cell cable so it can travel 18” Up with the cylinder.

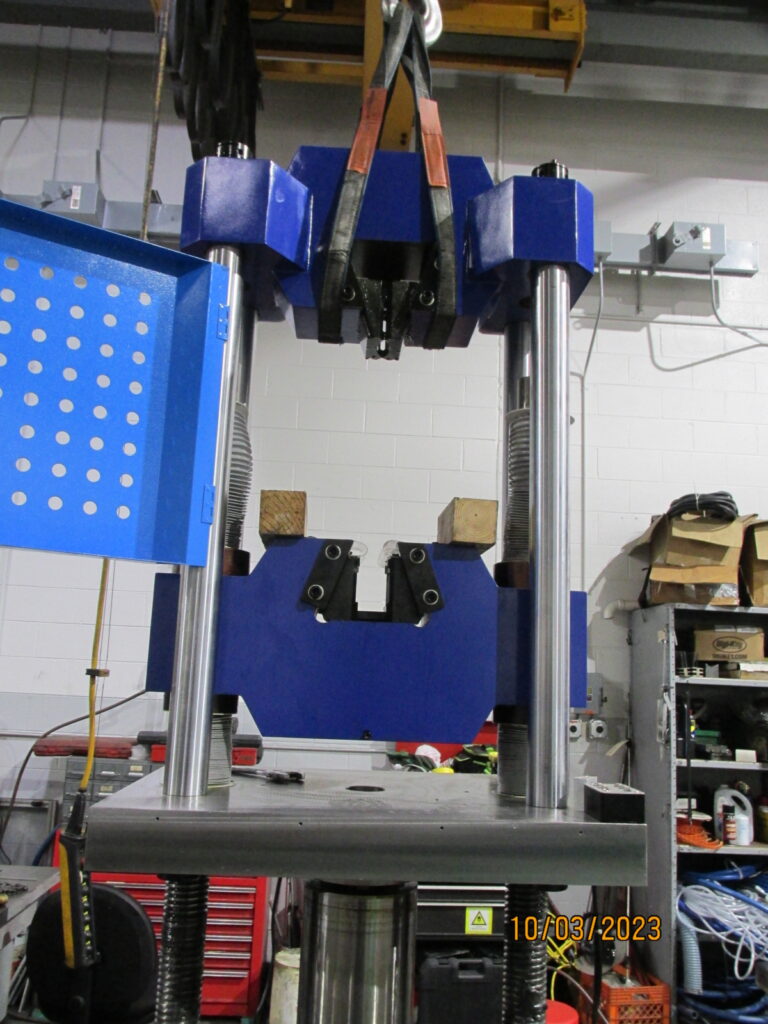

- Next you need to get a forklift/crane and raise the top crosshead up (Fig. 5) you should go up until the screw covers get bunched up also watch for any wires or hoses to be caught and pulled tight!

- Block up the base of the machine under the table and also place a block between the piston and the cylinder. You could also use a block between the crossheads if you felt that was needed

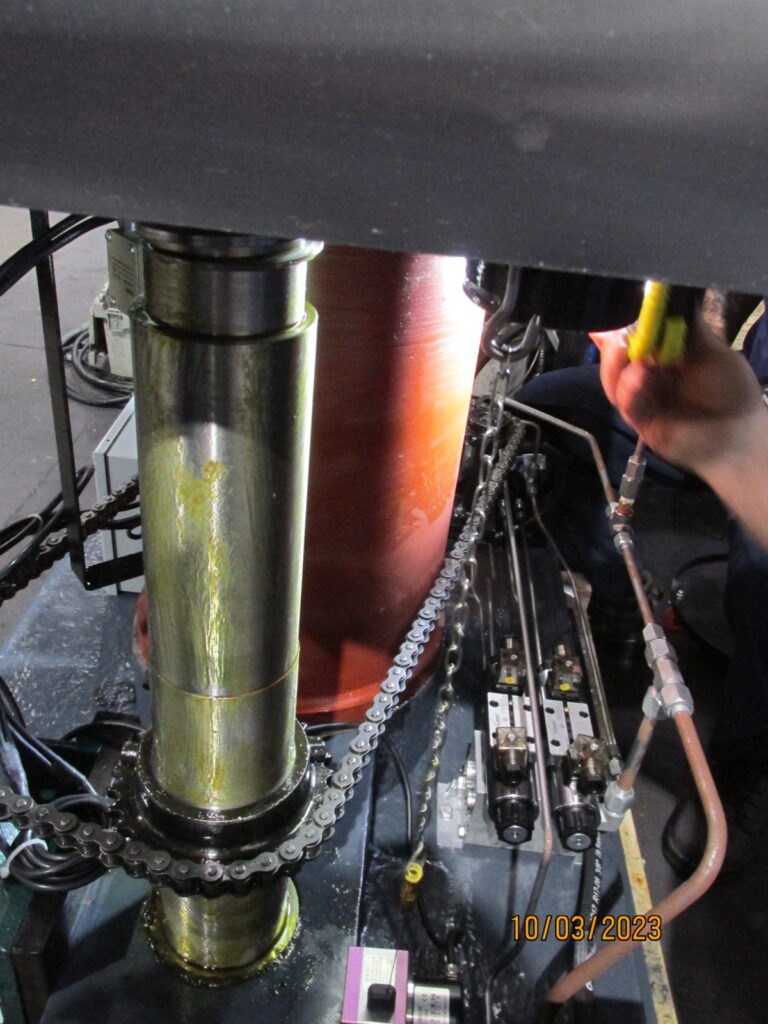

- This allows access to the seal (Fig. 6)

- Remove the outer hard seal

- Then remove the inner o-ring

- When installing the new outer seal do not kink the seal.

Please contact Frank Bacon Machinery For Sales, Support, Service or Questions!

586-756-4280