Reconditioned Tensile Tester: 60K (300 kN) Satec Baldwin Universal Testing Machine

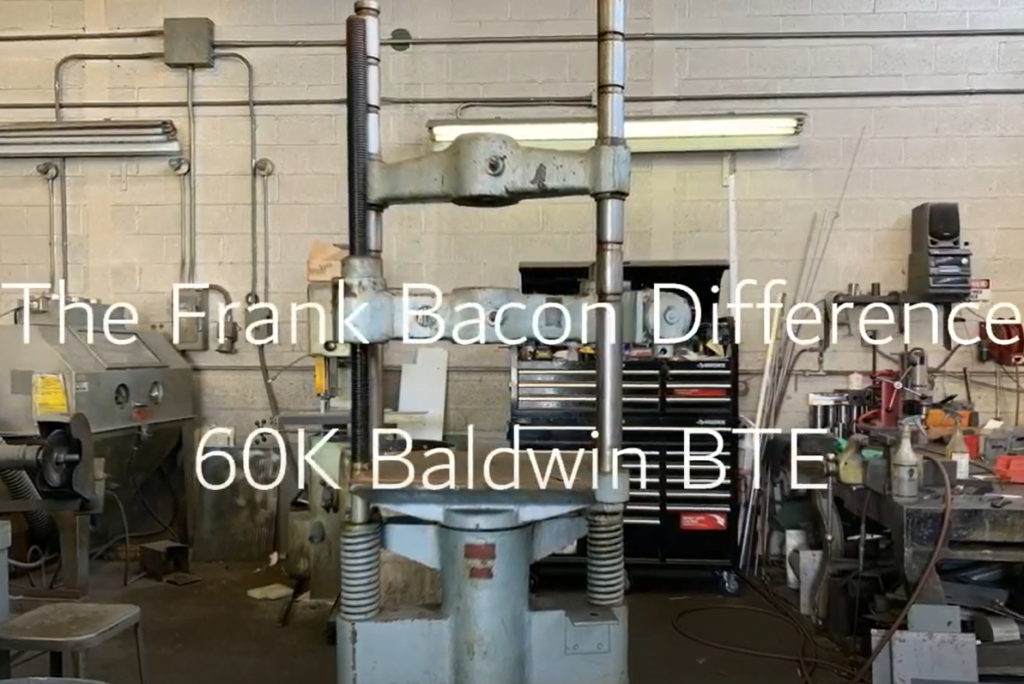

Watch the video below to see a full before and after transformation of this 1947 Tensile Tester 60K Satec Model 300kN Baldwin 60,00 lb capacity Universal Testing Machine.

This sold reconditioned Satec took the best of what the old machine had to offer and the retrofit brought it up to today’s standards. As seen before, the machine is worn down, old and dirty, but when we are done with it, it will be better than new. The whole machine will be reconditioned, taken apart, cleaned, serviced and certified. The Tensile Tester will receive a Frank Bacon a standard 1 year parts and labor warranty.

Hydraulic pumping system is all manual and manual loading and unloading lever. The customer who bought this machine wanted to keep the recondition cost effective, so we are keeping the machine manually controlled, however we are replacement the old dial indicator and adding a 3 channel digital indicating system. When completed, the 1947 machine will be fully certified to ASTM E8 standard load, displacement and speed, and a strain channel. For automatic calculation of yield, extensometers and deflectometers may be added.

Process reconditioning the 60K (300 kN) Satec Baldwin Tensile Tester

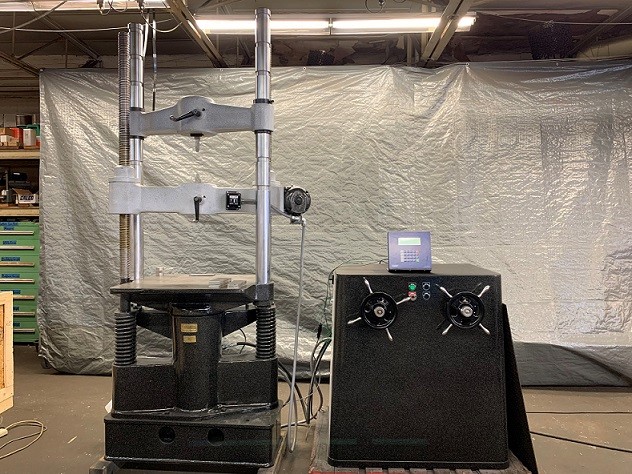

- BTE Hydraulic Power Supply Rear view

- BTE Hydraulic Power Supply Front View

- BTE Hydraulic Power Supply

In the video below we will take you through the process of reconditioning the Satec Baldwin. Our first step is to take the crossheads off the columns using a forklift. Next, the fully cleaned and painted machine is customized to customer preference. Then, the crosshead will be assembled and everything needs to be perfectly aligned and leveled.

The Satec Baldwin BTE is a pressure tranducer based machine with a tension and compression envelope. Test displayed in the video below. First, the specimen goes in the crosshead grips. The indicator shows live load, position and speed that sends information to the computer where the software can pull batch results from indicator to pull batch results and analysis from indicator to the computer to check calibration, test set up, and analysis set up from ease of the computer. We can outfit the machines with manual and computerized control options. Also, the micro needle valve, provides great control over the speed of the test on this Satec Tensile Tester. Next, we tighten the grip to have a consistent load. As the machine moves, we can speed it up a bit to .2, .25/min to have standard E8 pull to failure. There are wedge grips in the pocket to grip and maintain the specimen, the pinions are gearing to apply initial load to the specimen.

Further, on this Satec we rebuilt the pump, motor, electrical system, crosshead motor control and switching and limit switch. Also, a brand new encoder for position read out and pressure tranducer for load read out. After we have taken apart the machine and put it back together, all the data we receive is from new components. All of the parts and components of this Satec machine become rebuilt, repaired or replaced, from the columns and cylinders to the screws and seal. Brand new custom hydraulic cabinet, electrical system, computer and controller. The test frame construction paired with new hydraulics and a closed loop system.

The Frank Bacon Difference in Tensile Testers

Frank Bacon Machinery has been rebuilding and reconditioning tensile tester machines and Satec’s along with other Material Testing Equipment since 1953! We are a world leader in tensile testing sales. Our reconditioned Satec machines come with a 1 year parts and labor warranty and certified to current ASTM E10 requirements. They also come with our standard MDNA (Machinery Dealer National Association) 30 day satisfaction guaranteed return privilege.

What is a tensile tester? (Also known as a Universal Testing Machine (UTM))

Tensile testing also known as a tension testing applies a pulling force to a material to measure the material’s response to the stress. These tests determine how strong a material is and how much it can elongate before it breaks. Tensile testing determines tensile strength, yield strength, ductility, tensile yield and elongation. One of the most important properties we can determine about a material is its ultimate tensile strength (UTS). This is the maximum stress that a material sustains during the test.

60K (300 kN) Satec Baldwin– The Final Product

After reconditioning, our tensile testers are in pristine condition and the final product is like brand new. We completely replace the major components. This Satec has a brand new hydraulic power supply, electronics, controls and material testing software.

Call Frank Bacon Today!

Contact Frank Bacon Today!

If you have a Tensile Tester or Satec that needs reconditioning or need a Tensile Tester in your company, we have many in stock in various makes, models, sizes and price points. Contact us today to speak with a sales engineer!

Phone: 586.756.4280

Toll Free: 800- 394-4280