What are you testing with your testing machine?

This is one of the most important starting points when searching for a universal testing machine (UTM).

Material? Any specific ASTM, ISO or specifications you are testing to? Do are testing flat or round specimens?

Product? Full product test or assemblies? Push out test or pull out test?

Tension?

Compression?

Tension & Compression?

What force capacity machine are you looking for?

This is based on how much force it is going to take to test your samples to failure or a given proof load. Machines are rated in either Pound Force (LBF) or Kilonewton (kN).

How much horizontal and vertical opening do you need to test your part?

Different machines have different horizontal and vertical openings depending on make, model, capacity, and type. Depending on the size of the test parts and the fixturing required, an extra tall or extra wide machine may be necessary.

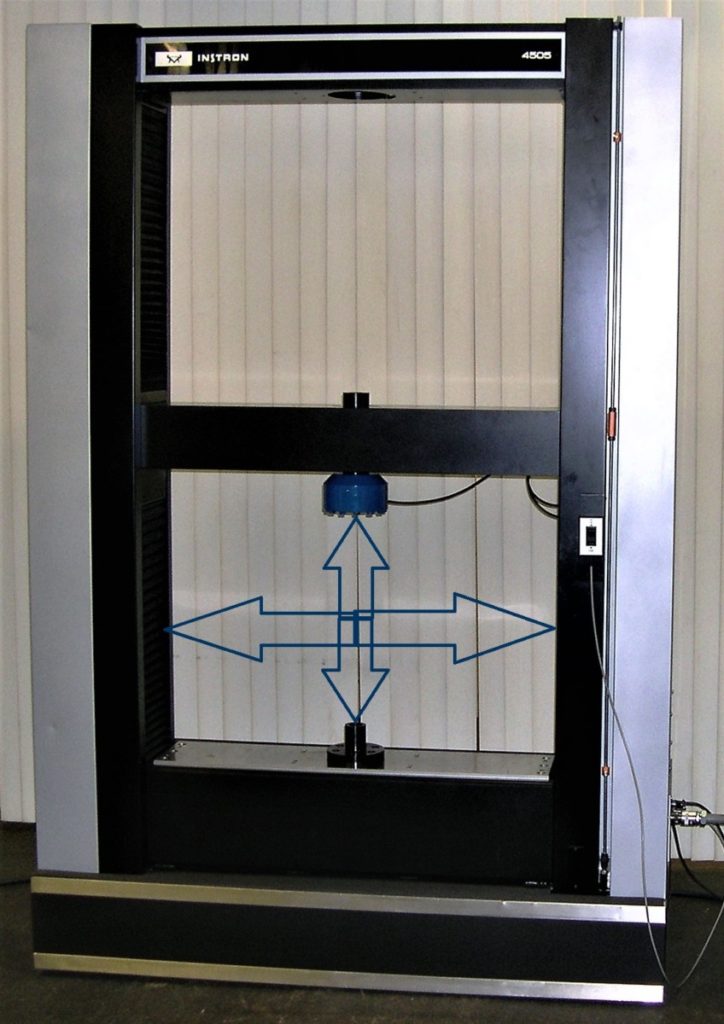

What Horizontal and Vertical Openings for Tensile Tester?

Do you want an Electromechanical (Screw Driven) or Hydraulic Testing Machine? Pros and Cons of Electromechanical (Screw Driven) vs. Hydraulic.

Screw Driven – Electromechanical Testing Machine

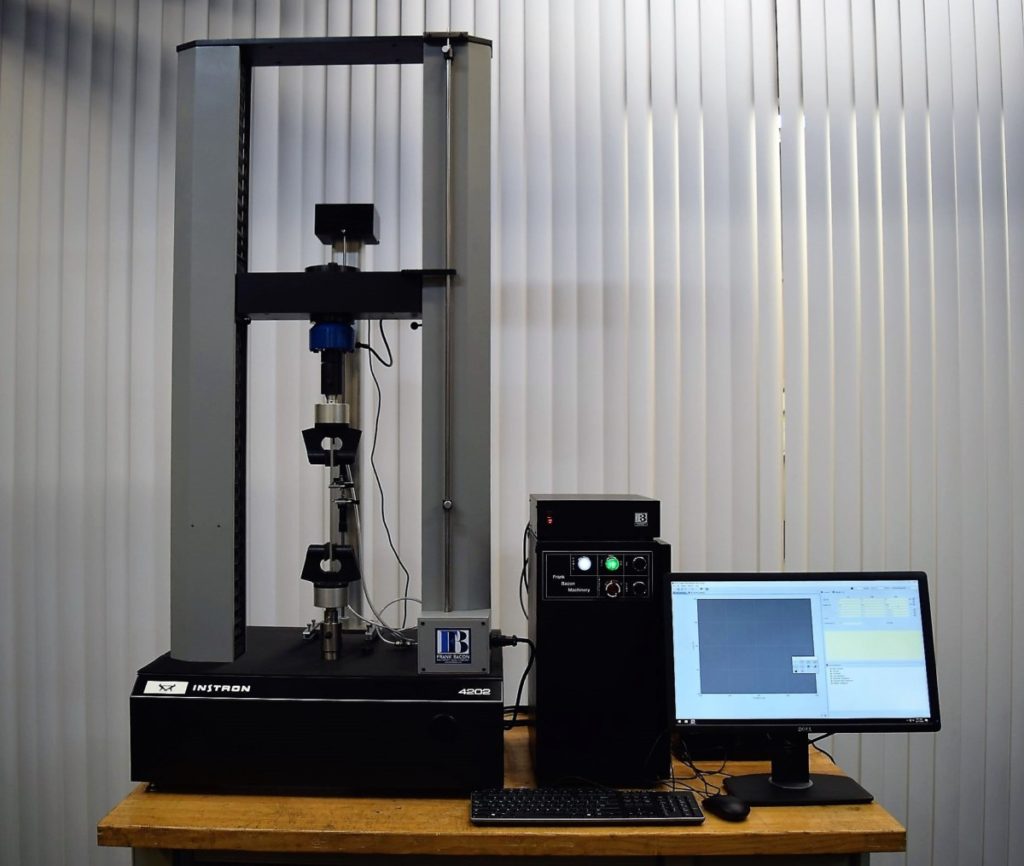

Electromechanical Screw Driven Tensile Test Machine – Instron

In mechanical testing there are two different classes of tensile testing machines; Screw driven, also known as electromechanical, and hydraulic.

Electromechanical (screw driven) tensile testers have recently become popular over the older hydraulic systems. An electromechanical machine is often quieter, takes up less space, is easier to move around, runs on less overall power, and requires less maintenance when compared to a hydraulic testing machine using a Hydraulic Power Unit (HPU).

The electromechanical or screw driven test frames typically use an electric motor and two elevation screws to run the crosshead up and down. The pros of the electromechanical test machines are that they offer a large range of test speeds by changing the speed of the motor. They also provide for longer crosshead travel distances (stroke) of up to 100 inches or more. Screw Driven machines are known for speed and position accuracy.

Furthermore, on a screw driven machine, due to the load cell arrangement under the crosshead, it is easier to adapt a variety of tooling and accessories (including grips, custom fixtures, additional load cells, environmental chambers) Compared to a hydraulic machine that is more difficult to fixture due to the dual test space nature of their design. Tension testing is performed in the top window (between top crosshead and middle crosshead) and compression testing is in the bottom window (between the middle crosshead and the table).

Cons of electromechanical are they are more expensive per force capacity compared to hydraulic machines (price per capacity). For example, a 60,000 Lbf (300kN) screw driven machine would be quite a bit more expensive compared to an equal force capacity hydraulic machine. They are also not as rugged and are more sensitive to debris and dirty environments than a hydraulic machine.

Hydraulic

- Hydraulic Testing Machine – Tinius Olsen

- Hydraulic Testing Machine – Tinius Olsen

Hydraulic testing machines load frames are extremely robust and rugged. With today’s modern servo hydraulic technology, they have become very accurate in load and position control. These testing machines incorporate a single or dual direction piston to move the table and attached top crosshead to apply the force.

One disadvantage of a hydraulic tensile tester is the test travel is limited by the piston stroke, which is typically 6-9 inches. Furthermore, hydraulic machines are much more cost effective when the need arises for generating high forces, normally 60,000 (Lbf) and more. Many times hydraulics are the only option when testing above 120K (600 kN).

Frank Bacon Machinery computerizes both hydraulic and screw driven test machines, offering control with servo motors or servo valves controlling the machine’s test speed/rate. Both may have the capability to control testing speed as measured by load rate, position rate, and strain rate.

Dual Space vs. Uni Space Machine Design

There are 3 main types of tensile tester design; Uni-Space, Dual Space, and Research Grade Dual Space.

Uni-Space tension and compression testing is performed below the moving crosshead. This is the most common for Screw Driven machines.

Dual Space machines perform tension in the upper window and compression in the lower window. Most commonly seen on hydraulic machines.

Research Grade Dual Space machines are able to do both tension and compression in both upper and lower windows.

- Uni-Space Tensile Tester Instron

- Dual Space Tinius Olsen Tensile Tester

- Dual Space Research Grade Instron Tensile Tester

What fixturing and tooling do you need?

- Flexural Fixture for Tensile Tester on Instron Machine

- Fastener Tooling for Tensile Tester

- Frank Bacon Wedge Grip

Fixture and tooling will be dependent on the type of testing you will be performing. Many of the ASTM, ISO testing have fixtures called for in the procedures. A universal testing machine UTM can perform thousands of different tests depending on the fixture. It is crucial to call a Frank Bacon Sales engineer to discuss the many possibilities out there.

Depending on your answers above you may need one of the following machines you can find in our extensive inventory at Frank Bacon Machinery Sales.

We offer Tinius Olsen, Instron, MTS, United and Frank Bacon Machinery etc. in various models with customization available.

We offer full remanufacturing and warranty on all makes and models.

Contact Frank Bacon Today!

If you have any questions or are looking for a tensile tester please contact a sales engineer at Frank Bacon. We will walk you through the whole process and give you a customized turnkey machine.

Phone: 586.756.4280

Toll Free: 800- 394-4280