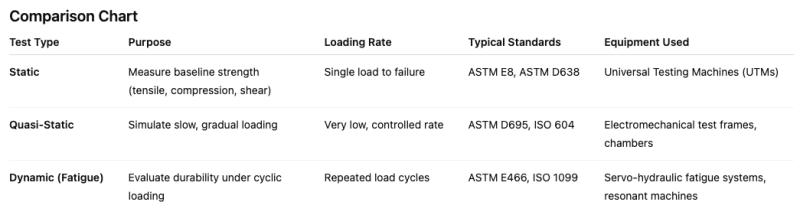

1. Static Testing

What it is:

Static testing applies a single load or force to a specimen and holds it until failure or deformation occurs. The goal is to measure a material’s ultimate strength, yield point, elongation, or compression properties.

Standards:

-

ASTM E8/E8M – Tensile testing of metals

-

ASTM D638 – Tensile testing of plastics

-

ISO 6892 – Metallic materials tensile testing

Equipment:

-

Universal Testing Machines (UTMs): Servo-hydraulic or electromechanical load frames equipped with load cells and extensometers.

-

Grips and fixtures designed for tension, compression, flexure, or shear tests.

-

Data acquisition systems for stress-strain curves.

Static testing is straightforward but essential—it provides the baseline mechanical properties for design.

2. Quasi-Static Testing

What it is:

Quasi-static testing is similar to static testing but performed at very slow, controlled rates of loading or displacement. It simulates conditions where materials or components experience gradual loads over time but not high-speed or repeated cycles.

When used:

-

Characterizing polymers and composites, which are strain-rate sensitive.

-

Simulating crash or crush scenarios in slow motion.

-

Verifying stiffness, creep, or relaxation behavior.

Standards:

-

ASTM D695 – Compressive properties of plastics

-

ISO 604 – Plastics compression testing

-

ASTM D790 – Flexural properties of plastics and composites

Equipment:

-

Electromechanical test frames with precise crosshead speed control.

-

Environmental chambers (for temperature or humidity exposure).

-

Specialized fixturing to mimic real-world applications (e.g., crush, indentation).

Quasi-static tests bridge the gap between simple static strength and high-speed dynamics.

3. Dynamic (Fatigue) Testing

What it is:

Dynamic or fatigue testing subjects materials/components to cyclic loading—repeated stresses or strains over thousands or millions of cycles. This evaluates long-term durability, crack growth, and failure modes.

Why it matters:

Most failures in real-world service occur due to fatigue, not single overload events. Aerospace, automotive, medical device, and energy industries all rely heavily on fatigue testing data.

Standards:

-

ASTM E466 – Fatigue testing of metallic materials

-

ASTM D7791 – Fatigue of plastics

-

ISO 1099 – Fatigue testing of metals

-

ASTM E647 – Crack growth rate

Equipment:

-

Servo-hydraulic fatigue test systems capable of high-frequency cyclic loading.

-

Resonant fatigue machines for efficient high-cycle testing.

-

Specialized sensors (extensometers, strain gauges, crack gauges).

-

Environmental chambers for simulating real-world service (temperature, corrosion, vibration).

Dynamic testing requires high-precision control systems that can apply millions of cycles without equipment drift or failure.

SUMMARY

-

Static testing → Single load until failure. Best for baseline material properties.

-

Quasi-static testing → Slow, controlled loading. Ideal for polymers, composites, and creep/relaxation studies.

-

Dynamic (fatigue) testing → Repeated cyclic loading. Critical for understanding durability and service life.

Each test type has its place in the product development lifecycle. Choosing the right method—and the correct equipment—depends on the material, application, and industry standards governing your project.