Basics of Tensile Testing

Basics of Tensile Testing

Tensile Testing is the most common method employed to determine the mechanical strength of an object. It involves the application of uniaxial force to measure the performance of a test specimen.

Instron 4507 Tensile Testing Machine available for sale at Frank Bacon Machinery Sales Co.

Working Definition of Tensile Testing

It is the measurement of the maximum or breaking load (tensile strength). Tensile strength is the resistance of a material to breaking when pulled. We depend on tensile strength in metal & alloys, rubber & plastics, leather & textiles.

Tensile testing is used in a variety of industries. In medical, safety and occupational. We want to make sure the seatbelts we use daily will not let go of our loved ones, and that the medical devices are strong enough to withhold procedures they are made for.

Types of tensile testing: Force and Material

Force:

Measuring the force it takes to pull a sample to break. An emphasis on breaking force and sometimes, elongation. Usually used to test a finished good. If need more information such as; how far the material stretches or how the material changes, a material test may be more suitable for your needs.

Material:

Material testing tells more than just break and elongation.

Measuring what happens between the start of the pull test and when the sample actually breaks. Gives more information. Emphasis on breaking force, yield, slope and elongation.

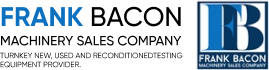

Yield is when sample reaches deformation. The test results shown below are on a stress v. strain graph. The analysis provides maximum load, maximum stress, and yield.

Stress V. Strain Frank Bacon Test Results

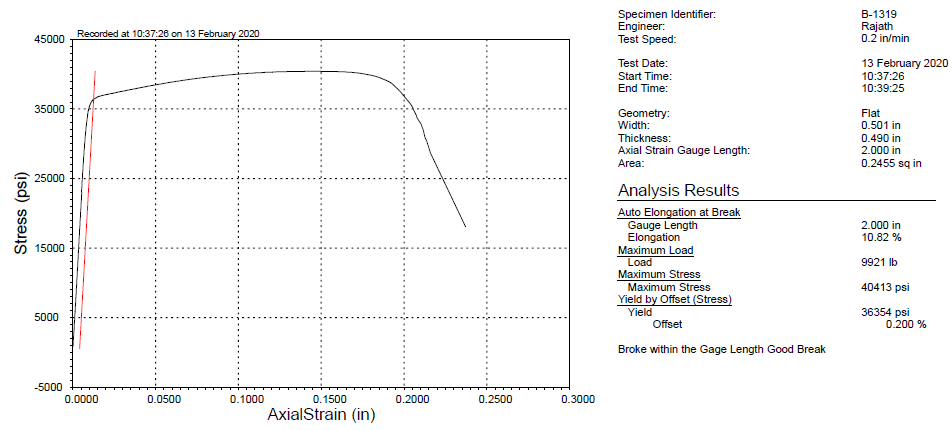

An extensometer may be used as well, a device that is used to measure changes in the length of an object.

Frank Bacon Machinery Sales Co. – Epsilon Extensometer

In a force test we don’t care when the sample deforms we just care when it breaks.

In a material test we care about what happens to material. For example: how far it stretches, when it becomes deformed. From there an assessment can be done on the sample to understand if anything needs to be changed and if more material needs to be added to it.

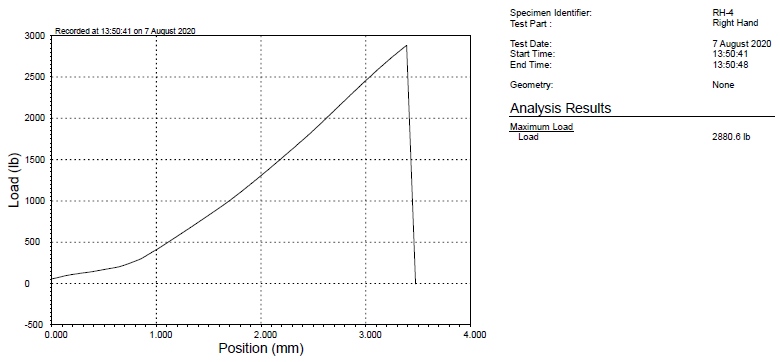

The test results below show are shown in load V. position. The customer wanted to find the maximum load as seen in the analysis results.

Stress V. Strain Frank Bacon Test Results

Industries that use tensile testing:

- Automotive (seatbelt)

- Medical/pharmaceutical

- Aerospace

- Cosmetics

- Beverage

- Education

- Manufacturing

- Electrical

Examples of Pull testing: Pull off, Peel/adhesion (ex: yogurt cup top pull off) make sure seals and can pull off easy enough, Shear/lap shear (test bonding), tear test. Thousands of ASTM and ISO, and industry standard specifications that can be followed.

Tensile Testing Devices

Tensile testing may be performed at a very basic level by using a handheld digital gage. Conversely, tensile testing may be done by complex tensile testing systems that have advanced testing software and accessories such as extensometers. These testing systems have the capability to run tests at a very precise velocity to a very precise target. Data from these tests helps produce high resolution data for both force and distance or stress and strain, so that very accurate measurements can be taken, analyzed and reported.

In conclusion, the results of a tensile test provide helpful data to describe the mechanical properties of the component or material. Tensile tests classify the sample’s ductility or brittleness and their elastic and plastic behavior. Tensile testing can be used to determine the material’s performance and suitability for use. Use of internationally accepted testing standards for tensile testing such as ASTM and ISO, assist in testing and help ensure products, components or materials meet specified design requirements.

If you are looking to bring testing in house and need a tensile testing system or are looking to outsource your testing needs contact a salesperson at sales@frankbacon.com today.

We offer Tinius Olsen, Instron, MTS, United and Frank Bacon Machinery in various models with customization available.

We offer full remanufacturing and warranty on all makes and models.

Contact Frank Bacon Today!

If you have any questions or are looking for a tensile tester please contact a sales engineer at Frank Bacon. We will walk you through the whole process and give you a customized turnkey machine.

Phone: 586-756-4280

Toll Free: 1-800-394-4280